Establishing a PVC window and door systems factory involves a multifaceted process that encompasses various stages, from planning and design to production, quality control, and distribution. In this very long description, we’ll explore the intricate details of setting up such a factory, highlighting the key considerations, processes, and factors involved.

**1. Planning and Feasibility Analysis:

- Market Research: Before embarking on the factory setup, thorough market research is essential. Analyze market trends, demand for PVC windows and doors, and competitor analysis to understand the industry landscape.

- Location Selection: Choose a strategic location that offers logistical advantages, proximity to raw material suppliers, access to skilled labor, and compliance with zoning regulations.

- Business Plan: Develop a comprehensive business plan that outlines your factory’s goals, budget, financing, and projected financial statements.

2. Factory Design and Infrastructure:

- Building Design: Collaborate with architects and engineers to design a factory layout that optimizes space, production flow, and safety standards. Consider factors such as production halls, storage areas, offices, and employee amenities.

- Utilities: Ensure a stable supply of electricity, water, and gas for production processes. Implement energy-efficient systems to reduce operational costs.

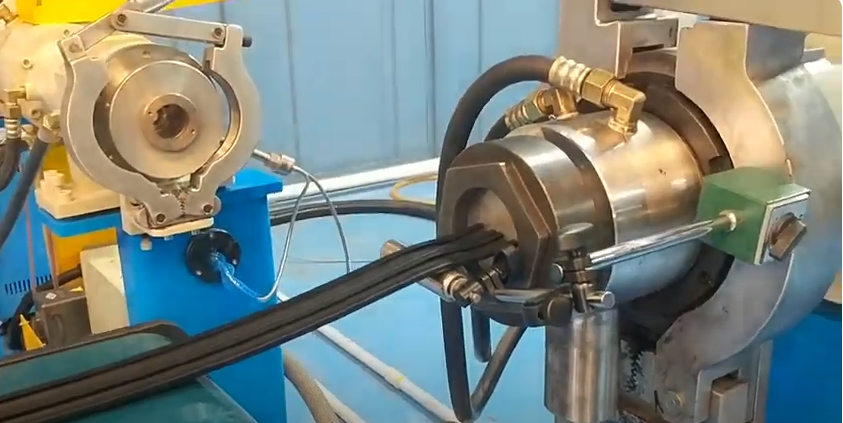

- Production Equipment: Invest in state-of-the-art machinery for extrusion, cutting, welding, glazing, and hardware installation. These machines should be selected based on your product range and production capacity.

3. Regulatory Compliance:

- Permits and Licenses: Obtain all necessary permits and licenses, including environmental clearances and compliance with building codes and safety regulations.

- Quality Standards: Adhere to industry-specific quality standards, such as ISO certifications, to ensure the production of high-quality PVC window and door systems.

4. Raw Materials and Suppliers:

- PVC Profiles: Establish partnerships with reliable PVC profile suppliers or consider setting up an in-house extrusion facility if feasible.

- Glass, Hardware, and Accessories: Source high-quality glass, hardware components (locks, handles, hinges), and accessories from reputable suppliers.

5. Production Processes:

- Extrusion: PVC profiles are extruded into the desired shapes and sizes using specialized machinery. Ensure strict quality control during this stage to maintain profile consistency.

- Fabrication: Profiles are cut, welded, and assembled to create frames and sashes. Advanced CNC machinery can enhance precision and efficiency.

- Glazing: Install glass panes, choosing from various options like double or triple glazing for energy efficiency and sound insulation.

- Hardware Installation: Attach locks, handles, hinges, and other hardware components to the window and door frames.

6. Quality Control:

- Implement rigorous quality control measures at every production stage to identify and rectify defects promptly.

- Conduct performance tests, including air and water infiltration tests, for compliance with industry standards.

7. Workforce:

- Recruit skilled technicians, machine operators, quality control personnel, and administrative staff. Provide training programs to enhance their skills and product knowledge.

- Emphasize safety protocols to prevent workplace accidents and ensure a healthy work environment.

8. Environmental Sustainability:

- Implement eco-friendly practices, such as recycling scrap PVC material, optimizing energy consumption, and minimizing waste generation.

- Consider sustainable packaging options for the finished products.

9. Marketing and Sales:

- Develop a robust marketing strategy to promote your PVC window and door systems through online and offline channels.

- Establish a network of distributors and dealers to reach a broader customer base.

10. Distribution and Logistics:

- Set up an efficient distribution network to deliver products to customers on time. Consider partnerships with logistics companies for transportation.

11. After-sales Service:

- Offer warranty and after-sales support to build trust with customers and ensure product satisfaction.

12. Financial Management:

- Maintain meticulous financial records and regularly assess the factory’s financial performance.

- Allocate budgets for maintenance, upgrades, and expansion as your business grows.

13. Continuous Improvement:

- Continuously monitor industry trends and technological advancements to stay competitive.

- Seek customer feedback and make product improvements accordingly.

Setting up a PVC window and door systems factory is a complex endeavor that demands meticulous planning, substantial investment, and a commitment to quality and sustainability. However, with proper execution and a focus on meeting market demands, such a factory can become a thriving business and contribute to the construction industry’s growth and development.