EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are versatile sealing components made from EPDM rubber, a synthetic elastomer known for its excellent resistance to weathering, ozone, UV radiation, and a wide range of chemicals. EPDM rubber gaskets are used in various industries and applications where a reliable and durable sealing solution is required. Here’s a closer look at EPDM rubber gaskets, including their key features, advantages, applications, and manufacturing processes:

Key Features:

- Chemical Resistance: EPDM rubber gaskets have outstanding resistance to a wide range of chemicals, acids, and alkalis, making them suitable for diverse applications.

- Weather Resistance: They are highly resistant to weathering, UV radiation, and ozone exposure, which allows them to maintain their integrity and sealing properties when exposed to outdoor conditions.

- Temperature Tolerance: EPDM gaskets can withstand both high and low temperatures, making them suitable for use in extreme environments.

- Excellent Elasticity: EPDM rubber is known for its excellent elasticity and flexibility, allowing gaskets to conform to irregular surfaces and maintain a tight seal.

- UV and Sunlight Resistance: EPDM rubber is resistant to degradation caused by UV rays and sunlight exposure, making it a preferred choice for outdoor applications.

Advantages:

- Durable: EPDM rubber gaskets have a long service life due to their resistance to environmental factors and wear and tear.

- Versatile: They can be used in various industries, including automotive, construction, HVAC, and manufacturing, for sealing applications ranging from weatherstripping to pipe gaskets.

- Cost-Effective: EPDM gaskets offer a cost-effective sealing solution due to their longevity and versatility.

- Eco-Friendly: EPDM rubber is generally considered environmentally friendly, as it can be recycled and has a low environmental impact during production.

Applications:

- Automotive Industry: EPDM rubber gaskets are used in vehicles for sealing doors, windows, hoods, and trunk lids to prevent water and air infiltration and reduce noise.

- Construction Industry: They are used in construction applications for weatherstripping doors and windows, sealing roofing, and as expansion joint gaskets.

- HVAC Systems: EPDM gaskets are employed in heating, ventilation, and air conditioning systems to provide air and water-tight seals in ducts, pipes, and access panels.

- Industrial Equipment: EPDM rubber gaskets can be found in various industrial machinery and equipment to provide sealing and vibration damping.

- Piping Systems: They are used as gaskets and seals in piping systems for water treatment, plumbing, and chemical processing to prevent leaks.

Manufacturing Process:

- Material Preparation: EPDM rubber is prepared by mixing ethylene, propylene, diene monomers, and curing agents. Fillers and additives may also be incorporated to achieve specific properties.

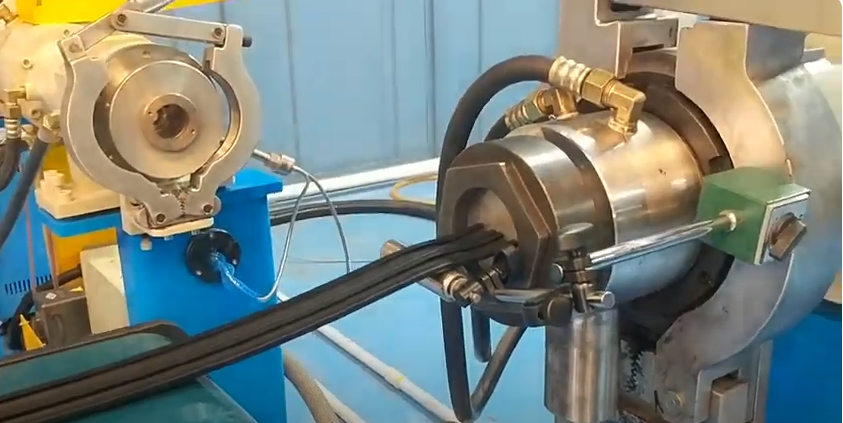

- Extrusion or Compression Molding: EPDM rubber is shaped into the desired gasket form through extrusion or compression molding processes.

- Curing: The gasket is subjected to a curing process, usually involving heat, to solidify the EPDM rubber and enhance its mechanical properties.

- Precision Cutting: The cured EPDM rubber may undergo precision cutting to create gaskets with the required dimensions and shapes.

- Quality Control: Each EPDM rubber gasket is subjected to quality control checks to ensure it meets the required specifications and standards.

In summary, EPDM rubber gaskets are highly versatile and durable sealing components used in various industries and applications. Their excellent resistance to chemicals, weathering, and temperature extremes makes them an ideal choice for sealing solutions where reliability is paramount. Whether used in automotive, construction, HVAC, or industrial settings, EPDM rubber gaskets provide effective and long-lasting sealing performance.