GRP (Glass Reinforced Plastic) pipe seals, also known as fiberglass pipe seals or GRP gaskets, are specialized sealing components designed to provide a secure and leak-free connection between GRP pipes or between GRP pipes and other pipe materials or fittings. These seals play a crucial role in various industries, including wastewater management, chemical processing, and infrastructure development. In this detailed description, we will explore the key features, advantages, applications, and manufacturing processes of GRP pipe seals.

Key Features:

- GRP Material: GRP pipe seals are typically made from glass fiber-reinforced plastic composite materials. This construction provides exceptional strength, durability, and resistance to corrosion, making them suitable for a wide range of applications.

- Sealing Efficiency: GRP pipe seals are designed to provide a high level of sealing efficiency. They create a reliable and leak-free connection, preventing the escape of fluids or gases in pipelines.

- Chemical Resistance: These seals exhibit excellent resistance to a wide range of chemicals, acids, and corrosive substances, making them ideal for use in industries where chemical processing is involved.

- Temperature Tolerance: GRP pipe seals can withstand a broad temperature range, from extreme cold to high heat, without losing their sealing properties.

- Customization: Manufacturers offer GRP pipe seals in various sizes, shapes, and designs to accommodate different pipe diameters and connection types. This customization ensures a precise fit and sealing performance.

Advantages:

- Corrosion Resistance: The GRP material used in these seals is highly resistant to corrosion, making them a suitable choice for applications in aggressive environments.

- Longevity: GRP pipe seals have a long service life due to their durability and resistance to wear and tear. They require minimal maintenance, reducing downtime and replacement costs.

- Chemical Compatibility: The seals’ resistance to chemicals and acids makes them invaluable in chemical processing plants and industries dealing with hazardous substances.

- Sealing Performance: GRP pipe seals offer excellent sealing performance, ensuring the integrity of pipelines and preventing leaks that could lead to environmental and safety hazards.

Applications:

- Wastewater Management: GRP pipe seals are commonly used in wastewater treatment plants and sewer systems to prevent leaks and ensure the efficient flow of sewage and treated water.

- Chemical Processing: Chemical manufacturing facilities utilize GRP pipe seals to maintain leak-free connections in pipelines carrying corrosive chemicals and acids.

- Infrastructure Development: These seals are essential in infrastructure projects such as water supply systems, drainage systems, and underground pipelines.

- Oil and Gas Industry: GRP pipe seals find applications in the oil and gas sector, particularly in offshore drilling platforms and pipelines where corrosion resistance and sealing integrity are critical.

- Industrial Piping: Various industries, including mining, power generation, and manufacturing, use GRP pipe seals to connect and seal pipes carrying different fluids and gases.

Manufacturing Process:

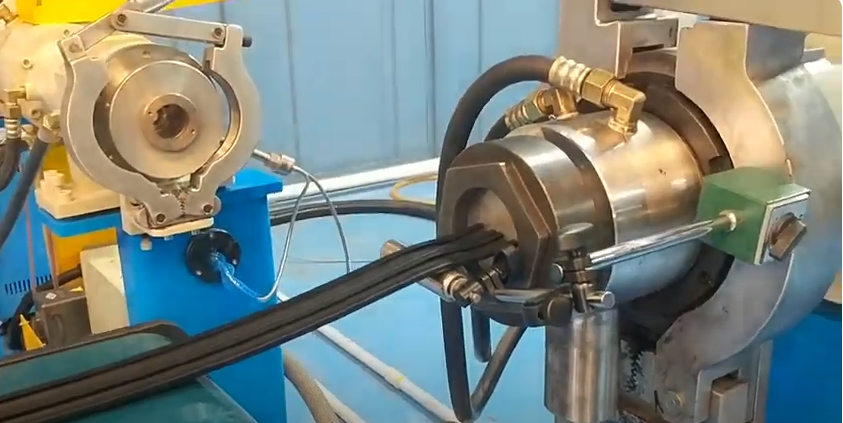

- Material Preparation: The manufacturing process starts with the preparation of GRP composite materials, which typically consist of layers of glass fibers impregnated with a thermosetting resin.

- Molding: The prepared GRP material is molded into the desired shape and size, taking into consideration the specific design requirements of the seal.

- Curing: The molded GRP seals are subjected to a curing process, typically involving heat and pressure, to harden the resin and ensure the structural integrity of the seal.

- Quality Control: Each seal undergoes rigorous quality control tests to verify its dimensions, mechanical properties, and sealing performance.

- Customization: Manufacturers may offer customization options to tailor the seals to the precise requirements of clients, including different pipe diameters and connection types.

In conclusion, GRP pipe seals are critical components in a wide range of industries, providing a reliable and long-lasting solution for sealing GRP pipes and connections. Their exceptional durability, resistance to corrosion, and sealing efficiency make them a valuable asset in infrastructure development, wastewater management, and various industrial applications. Whether in harsh chemical environments or extreme temperature conditions, GRP pipe seals contribute to the safe and efficient operation of pipelines, ensuring environmental protection and operational reliability.