EPDM (Ethylene Propylene Diene Monomer) rubber seals, often referred to as EPDM gaskets or EPDM rubber gaskets, are essential sealing components used in various applications across different industries. EPDM rubber is known for its outstanding resistance to environmental factors, including weathering, UV radiation, ozone, and chemicals. EPDM rubber seals are versatile and reliable, making them suitable for a wide range of sealing needs. Here is an in-depth look at EPDM rubber seals, including their key features, advantages, applications, and manufacturing processes:

Key Features:

- Chemical Resistance: EPDM rubber seals exhibit exceptional resistance to a wide range of chemicals, acids, alkalis, and solvents, making them suitable for applications where exposure to corrosive substances is a concern.

- Weather Resistance: They have excellent weather resistance and can withstand prolonged exposure to outdoor elements, including UV radiation and ozone, without deteriorating.

- Temperature Tolerance: EPDM rubber seals can perform effectively across a broad temperature range, from extreme cold to high heat, without losing their sealing properties.

- Elasticity and Flexibility: EPDM rubber is highly elastic and flexible, allowing seals to conform to irregular surfaces and maintain a secure and tight seal.

- Durability: EPDM rubber seals are known for their durability and resistance to wear, tear, and compression set, ensuring a long service life.

Advantages:

- Versatility: EPDM rubber seals are versatile and suitable for a wide range of industries, including automotive, construction, HVAC, plumbing, and manufacturing, due to their adaptability and broad compatibility.

- Weatherproofing: They provide effective weatherproofing by preventing the ingress of water, air, dust, and outdoor contaminants, making them ideal for sealing doors, windows, and other outdoor applications.

- Chemical Resistance: EPDM rubber seals are capable of maintaining their integrity when exposed to various chemicals and corrosive substances, ensuring reliable sealing performance.

- Temperature Range: Their ability to function in extreme temperature conditions makes EPDM rubber seals suitable for both cold and hot applications.

- UV Resistance: EPDM rubber is highly resistant to UV radiation, making it ideal for outdoor applications exposed to sunlight.

Applications:

- Automotive Industry: EPDM rubber seals are extensively used in vehicles for sealing doors, windows, hoods, trunk lids, and various engine components to prevent water, air, and noise infiltration.

- Construction Industry: They are employed in construction applications for weatherstripping doors and windows, sealing roofing, acting as expansion joint gaskets, and sealing building envelopes.

- HVAC Systems: EPDM rubber seals provide air and water-tight seals in heating, ventilation, and air conditioning (HVAC) systems for ducts, pipes, access panels, and more.

- Plumbing Systems: EPDM rubber seals serve as gaskets and seals in piping systems for water treatment, plumbing, and chemical processing to prevent leaks and ensure secure connections.

- Manufacturing and Industrial Equipment: These seals are used in various industrial machinery and equipment to provide sealing, insulation, and vibration damping.

Manufacturing Process:

- Material Preparation: EPDM rubber is prepared by compounding ethylene, propylene, diene monomers, curing agents, and additives to achieve the desired properties.

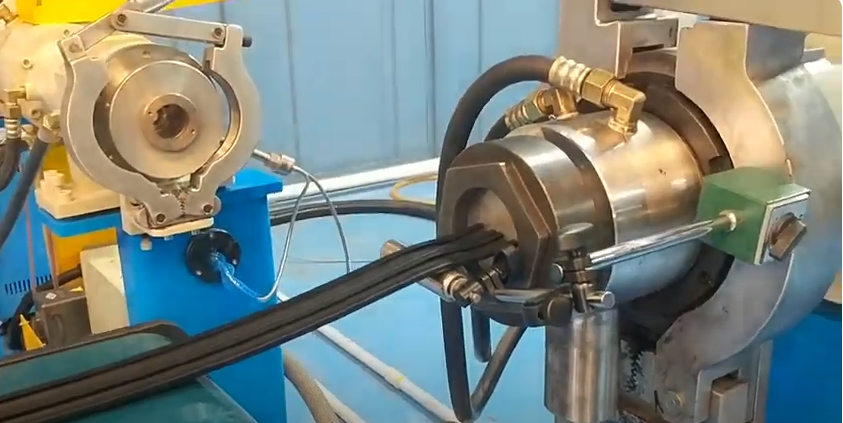

- Extrusion or Compression Molding: The EPDM rubber compound is shaped into the desired seal form through extrusion or compression molding processes.

- Curing: The molded or extruded EPDM rubber is subjected to a curing process, often involving heat, to solidify the rubber and enhance its mechanical properties.

- Precision Cutting: The cured EPDM rubber may undergo precision cutting to create seals with the required dimensions and shapes.

- Quality Control: Each EPDM rubber seal undergoes rigorous quality control checks to ensure it meets the specified standards and specifications.

In conclusion, EPDM rubber seals are dependable and adaptable sealing components used in various industries for a wide range of applications. Their exceptional resistance to environmental factors, chemical resistance, temperature tolerance, and durability make them an ideal choice for sealing solutions where long-term performance and reliability are crucial.